Asbestos | Frequently Asked Questions

What is asbestos?

Asbestos is a naturally occurring mineral. It contains fibres that are strong, heat resistant, water resistant and has very good insulating properties. Asbestos fibres are up to 200 times smaller that a human hair. This means they can be so small that you cannot see them with the naked eye, they stay airborne for a long time and are easily breathed into the lungs.

What types of asbestos are there?

Asbestos in Australia is commonly classed into three different types.

- Chrysotile (White asbestos)

- Amosite (Brown asbestos)

- Crocidolite (Blue asbestos)

The colours are not typically reflected in a product containing that type of that asbestos. The colour refers to how the fibres look under a microscope when they’ve been stained with an oil and looked at with UV light.

What are the differences in types?

White asbestos belongs to the serpentine group, when you look at it under a microscope it has an ‘s’ or snake shape. Due to its shape it is less likely that this type of asbestos will penetrate your lung wall.

Brown and Blue asbestos both belong to the amphibole group, when you look at them under a microscope they have a dart like shape. This makes it easier for these fibres to penetrate the lung wall. When brown asbestos fibres are damage they break across their width, which means there are more of them but they do not get any finer. Blue asbestos fibres break long their width, which means the more they are damaged the finer they become and the easier it is for the fibres to penetrate your lung wall.

Blue asbestos is considered the most dangerous, followed by brown and then white. It’s important to emphasise that just because blue is the worst, brown or even white cannot be considered safe. All asbestos is dangerous. The different types were used in certain products and often its the stability of the end product, rather than the type of asbestos in it that determines how dangerous it is.

Conventional wisdom said that asbestos related diseases can take up to 50 years to develop and show symptoms. But recent research has found that once exposed the risk of developing an asbestos related disease remains throughout your entire life. This means that the earlier in life you are exposed, the longer you have for symptoms to develop. There maybe some treatments that prolong the life of sufferers of asbestos related disease, but there are no known cures.

What health risks does asbestos pose?

Asbestos can have negative health outcomes if fibres are breathed into the lungs. Your natural defences do provide some protection (nose hair, coughing up and swallowing etc), but due to how small asbestos fibres are, some asbestos can remain in your lungs.

Asbestosis is one of the most condition people ask about. This is where asbestos fibres that are stuck in the lung cause scarring. It does progressively get worst, but mainly reduces quality of life due to struggling to breathe rather than being fatal.

Mesothelioma is the other condition that is commonly talked about in the media. This is a cancer of lining around the lungs and abdomen, and is caused by fibres penetrating the lung wall and damaging the cells there which become cancerous over time. Average time from diagnosis till death from Mesothelioma is 5-6 months. Other health effects include lung cancer and benign pleural diseases, which are non-cancerous diseases that affect the linings around the linings of the lung and abdomen.

When did they stop using asbestos?

In Queensland asbestos building materials were banned in 1990 and all forms of asbestos have been banned nationally since 31 December 2003. This does not guarantee that homes and buildings built post 1990 are asbestos free. In our experience we have encountered a home built as late as 1996 that had products which were tested and found to contain asbestos. It is always safer to have a sample analysed by a NATA approved laboratory rather than assume that a product is asbestos free.

Where was asbestos used?

Asbestos was commonly used in a variety of building materials throughout Australia. The 1940s till the late 1980s was it’s hey day, and most buildings constructed during this time contain asbestos somewhere.

In Queensland the most common domestic uses were for roof linings, internal wall and ceiling linings, vinyl floor sheeting and tiles, external cladding, fences, sheds linings, and compressed deck sheeting. Depending on the age of the house the entire building can be made of asbestos materials except for the timber frame, the floors and foundations.

During the 60s and 70s the VJ timber wall linings that are so popular today were considered unfashionable, so often in Queenslanders the VJ walls and ceilings where covered with asbestos sheeting.

In the commercial and industrial environment asbestos was very popular for it’s heat resistance and insulating properties. Entire industrial sheds were often lined in corrugated asbestos sheeting, and in commercial buildings it’s very common to find internal wall and ceiling linings, as well as vinyl floor coverings that contain asbestos.

In these environment there are simple too many asbestos products to list in detail here. All commercial buildings built prior to 1990 should have an ‘Asbestos Register’ that clearly identifies any asbestos material on the property and the condition it’s in. Please refer to your site’s asbestos register for a detailed report.

Identifying Asbestos

Types and examples of asbestos-containing materials

Asbestos in Building Materials

- Ceiling Tiles and Lay-in Panels Chalkboards

- Spray-Applied Insulation Roofing Shingles

- Blown-in Insulation Roofing Felt

- Fireproofing Materials Base Flashing

- aping Compounds (thermal) Thermal Paper Products

- Packing Materials (for wall/floor penetrations)

- Fire Doors

- High Temperature Gaskets Caulking/Putties

- Laboratory Hoods/Table Tops Adhesives

- Laboratory Gloves Wallboard

- Fire Blankets Joint Compounds

- Fire Curtains Vinyl Wall Coverings

- Elevator Equipment Panels Spackling Compounds

- Cement Pipes Elevator Brake Shoes

- Cement Wallboard HVAC Duct Insulation

- Cement Siding Boiler Insulation

- Asphalt Floor Tile Breaching Insulation

- Vinyl Floor Tile Ductwork Flexible Fabric Connections

- Vinyl Sheet Flooring Cooling Towers

- Flooring Backing Pipe Insulation

- Construction Mastics (floor tile, carpet, ceiling tile, etc.)

- Heating and Electrical Ducts

- Acoustical Plaster Electrical Panel Partitions

- Decorative Plaster Electrical Cloth

- Textured Paints/Coatings Electric Wiring Insulation

Friable Asbestos

- Asbestos-rope door gaskets in wood stoves

- Loose fill roofing insulation (not common)

- Spray-on insulation or soundproofing

- Low-density asbestos fibre board

- Insulation on hot-water pipes, domestic heaters and stoves (e.g. lagging)

- Backing material on floor tiles and vinyl flooring

- Carpet underlay (not common)

- Textured paints, decorative ceiling coatings

- Heat-resistant fabrics

- Brick and plaster sealants, fillers and some adhesive products

- Hail or fire damaged, or badly weathered asbestos cement materials.

Additional resources

Common locations of materials containing asbestos in a house (PDF, 4.8MB)

Example of a house with a concrete or clay (terracotta) tiled roofCommon locations of materials containing asbestos in a 1970’s house (PDF, 476KB)

Example of a house built in the 1970sCommon locations of materials containing asbestos in a commercial building (PDF, 583KB)

Example of a commercial buildingAsbestos: A guide for householders and the general public, Australian Health Protection Principal Committee, Canberra, 2012 (PDF, 3.10 MB)

Environmental Health Subcommittee (EnHealth)

Further information and resources on asbestos, are available on the Queensland Government’s website at https://www.health.qld.gov.au/asbestos/.

How is asbestos removed?

Construction and demolition are dangerous activities and asbestos removal particularly so. Advanced Deconstruction trains its staff to exceed the highest industry standards so they are able to identify and manage risks before they become a problem.

We like to compare asbestos removal to driving a car. Driving an old Volvo, at 100 km/h without a license, and without a seat belt in a 60 km/h zone ignoring all the road signs and traffic lights is very dangerous. However, with appropriate training (a license),the right safety equipment (a seat belt and a well maintained vehicle), and by following the road rules we can reduce all those risks so that it becomes a much safer activity.

This is exactly what we do during asbestos removal. We have the right Personal Protection Equipment (respirators, disposable overalls and gloves);we have the training (all our staff have the new VET qualifications to remove friable asbestos as well as regular training courses, refreshers, and on-the-job skill development); our safety procedures and systems ensure that we are aware of and follow all the rules and regulations that apply to asbestos removal.

All of these factors change a very dangerous activity, into a safely managed and risk controlled activity.

Asbestos Removal Procedures

When doing asbestos removal there are some basic principles that apply to all tasks. By following these and then tailoring specific solutions to risks identified in your job we are able to make sure that we protect our health and yours.

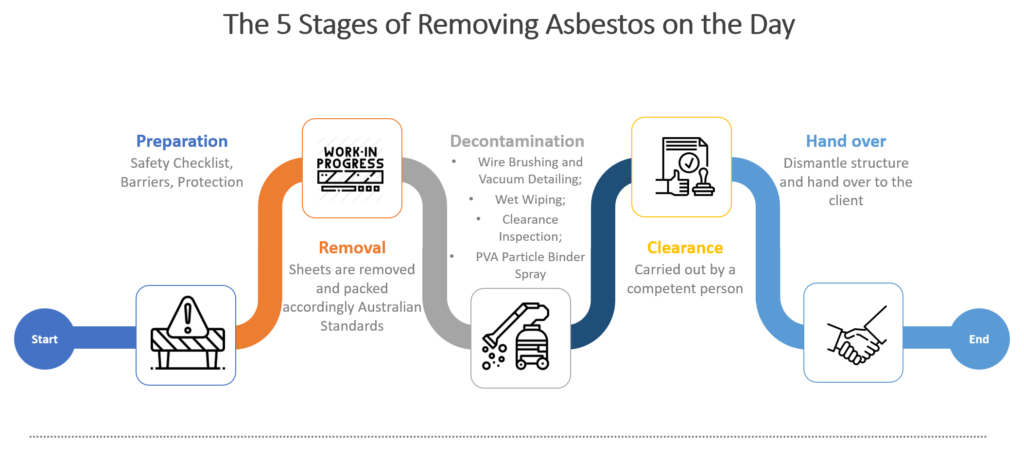

The 5 stages of an Asbestos Removal Job

- Preparation

- Removal

- Decontamination

- Clearance

- Hand over

1. Preparation

The work before asbestos removal starts is some of the most important. Before we arrive on site safety documentation is prepared, the government is notified of the work, and we give you a notification letter to pass out to your neighbours. Our staff start their day with a safety checklist and review of your project before they touch any tools.

Once these vital safety reminders and checks have been completed they can begin preparing the site. This includes establishing an asbestos work area (which allows us to control the movement of dust and air so that we can prevent cross-contamination) and removing any obstructions that prevent us from removing the asbestos easily.

The asbestos work area is the main location of the asbestos removal. In this area, we use plastic sheeting to cover floors, windows, doorways and other openings. This prevents dust from moving outside our work area and contaminating clean areas. By keeping this area as small as possible it saves us time and saves you money.

Common obstructions to removing asbestos include cabinetry, skirting boards, architraves, and cornices. We establish the plastic sheets to control dust movement before removing obstructions, as some of them are stubborn and can damage the asbestos sheeting during their removal. We also don’t recommend removing obstructions yourself for the same reason. It doesn’t take long for us to remove them and it’s much safer when we do it.

2. Removal

The removal of asbestos is the simplest part of our work. The main priority during removal is to limit the release of asbestos fibres. We do this by removing sheets whole wherever possible, and we keep the sheets wet with a fine mist of water or glue. Once sheets are removed they are either wrapped in plastic packs at the source of removal or where it is safe to do so they are wet misted and carried along a clearly defined transit route to a plastic lined asbestos skip or cartage truck.

3. Decontamination

Decontamination is the most time consuming and important part of any asbestos removal. Most of our staff’s training is focused on decontamination activities. The methods we use have been monitored and approved by independent occupational hygienists and we regularly have air-monitoring devices used to demonstrate exactly how clean our work areas are once decontamination is finished.

Our decontamination process has four overlapping methods that reduce the risk of human error and ensures that the asbestos work area is safe to re-occupy once we are finished.

These four methods are:

1) Wire brushing & vacuum detailing (with asbestos rated HEPA vacuum cleaners).

2) Wet wiping of all dust catching surfaces.

3) Clearance inspection.

4) PVA particle binder spray coating of the enclosure

Decontamination is about being thorough and methodical. Typically we will start by removing any fixings that were holding the asbestos in place (IE nails) then we will begin vacuum cleaning from the highest point in the work area and work our way down to ground level. Our experience in this area means we are able to identify hidden or difficult to reach locations that asbestos debris and fibres can settle. By taking the time to find these locations we make sure there is no asbestos left in the work area for someone to stumble across during a renovation or demolition.

Once vacuum cleaning has been completed the entire area is wet wiped to ensure that all dust catching surfaces are clean to touch. A clearance inspection is carried out and then the entire work area/enclosure is coated with a fine mist of PVA glue. This glue spray method means that any unseen fibres which may be stuck in timber, or buried in nail holes are sealed permanently, preventing them from getting into the air.

4. Clearance

Clearance inspections act as quality assurance and are vital to safe and legal asbestos removal. Many asbestos removal firms will not mention or will try to avoid clearance inspections and certificates. They are perceived by many in the industry as time consuming and unnecessary. This could not be further from the truth. AD has been conducting clearance inspections and issuing clearances certificates for all our work for many years. With the recent revision of the Code of Practice, other companies have now been forced to do the same.

A clearance inspection is carried out by a competent person (either a qualified Asbestos Removal Supervisor or a Licensed Asbestos Assessor) who was independent of the asbestos removal work (IE someone who was not involved in the preparation, removal or decontamination stages of the job). The process involves inspecting the asbestos work area to make sure there is no visible dust or debris (of any kind, not just asbestos).

A clearance inspection is typically carried out with a torch and a small screw driver. The inspector is followed by Advanced Deconstruction’s staff who will fix any problems identified as the inspection is conducted. Once the inspector is satisfied that the work area is safe and clean with no visible dust or debris he will instruct Advanced Deconstruction’s staff to begin the glue spray process. It is vital that the inspection occurs prior to the work area being sprayed with glue. Once the glue is sprayed no further cleaning can be carried out, and if there is still dust and debris in the enclosure the glue with push that dust up into the air. Glue is sprayed on any surface that was in direct contact with the asbestos in order to seal as a final quality control measure.

5. Hand over

Once the glue has been sprayed the work area can be deconstructed. Plastic drop sheets are rolled up carefully and disposed of as asbestos waste, and a final vacuum detail and wet wipe of the floor to clean up any overspray from the glue and leave the area as clean it can be for hand over. All dust barriers and door seals are left in place until this final vacuum detailing is completed, as they protect the clean areas of the site from cross contamination they are the last control measure to be removed.

If at any stage during the hand over phase we discover asbestos debris or residues we undertake thorough decontamination again as well as another Clearance Inspection.

When all of the dust barriers, signage, and door seals have been dismantled the area is ready for hand over to the client and is safe to re-occupy.